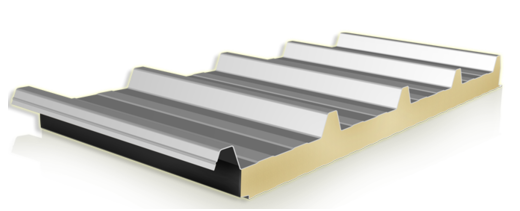

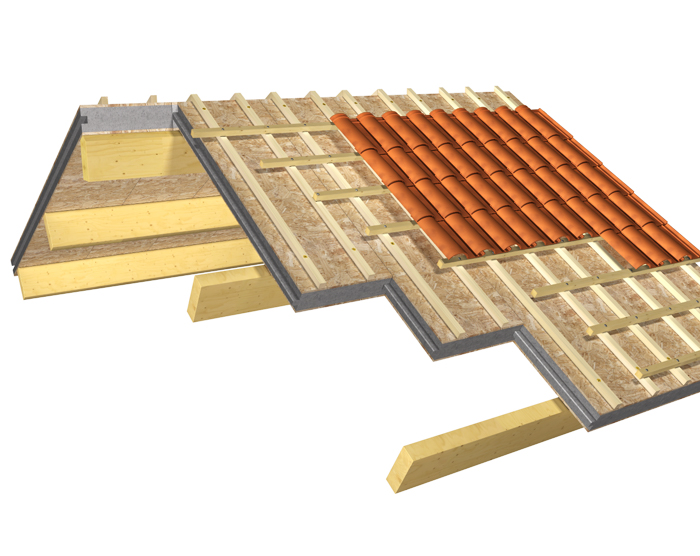

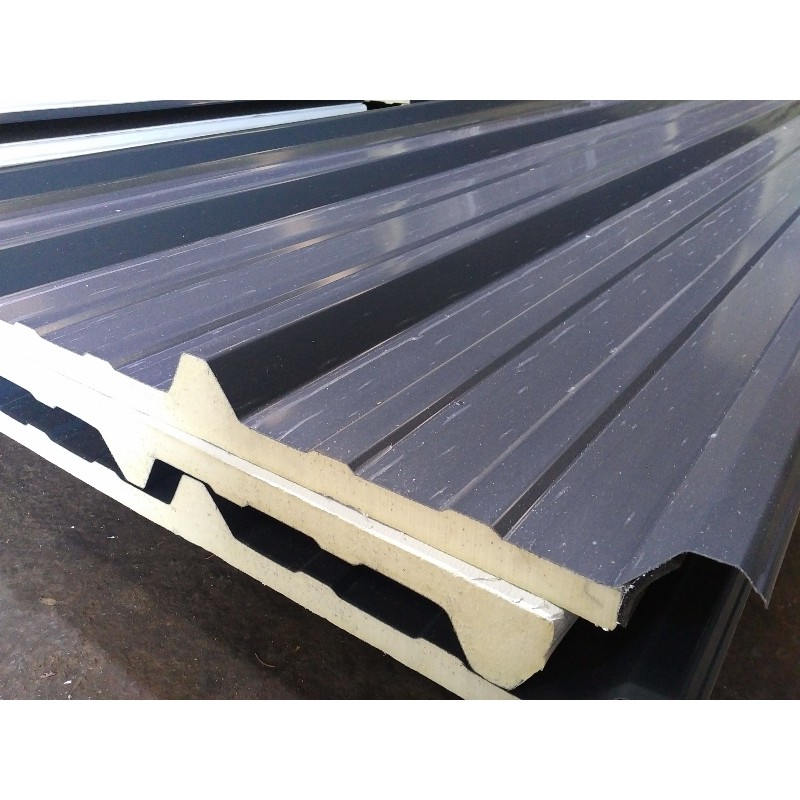

Sandwich panels (sometimes referred to as composite panels or structural insulating panels(SIP)) consist of two layers of a rigid material bonded to either side of a lightweight core. The three components act together as a composite; that is, the combination of the characteristics of the components results in better performance than would be possible if they were acting alone.

The lightweight core keeps the two faces in the correct position, resists shear forces, and provides insulation, while the two faces provide durability, weather and impact resistance, and resist in-plane forces of tension and compression.

Sandwich panel systems include the panels themselves, the joints between them, fixings (often concealed) and a support system.

Sandwich panels are widely used as an external cladding for single and multi-storey buildings, where they are required to provide weather resistance, and resistance to wind-loading, access loads, self-weight and so on. However, they are also used to create insulated internal envelopes, ceiling panels, partitions (for example in cold stores) and for fire-resisting compartment walls.

Building types that commonly feature sandwich panels include:

Industrial buildings and processing plants.

Temporary buildings.

Storage buildings.

Clean rooms.

Agricultural buildings.

Shopping centres.

Sports facilities.

Transport buildings.

Materials

The outer faces of sandwich panels are most commonly made of metals such as:

Hot-dip galvanized steel sheet.

Aluminium.

Zinc.

However, other materials that can be used include:

Preecast concrete, sometimes clad with other finishes such as brick.

Cement board.

Glass fibre reinforced polypropylene.

Poly vinyl chloride (PVC).

Magnesium oxide board (MgO).

Plywood.

Oriented strand board (OSB).

Glass reinforced plastic (GRP).

Cladding systems typically include a rigid polyurethane core, but other core materials include:

Expanded polystyrene (EPS).

Extruded polystyrene (XPS).

Mineral wool (rock fibre) (MWRF).

Modified Phenolic foam (MPHEN).

Polyisocyanurate (PIR).

Folded metal, paper, aramid and carbon fibres. See Foldcore for more information.

Honeycomb materials (such as Polypropylene).

Properties

Sandwich panels can be selected because of their:

Ease and speed of installation.

Rigidity.

Thermal, fire and sound insulation.

Airtightness

Robustness and durability

Low maintenance / cleaning requirements.

Low capital cost.

Low lifetime costs

Chemical and biological resistance

Light weight.

Weather resistance.

Dimensional stability.

Availability as standard products off-the-shelf.

However, There can be particular difficulties associated with buildings containing combustible sandwich panels